After receiving a notification about an item being out of stock, most consumers may simply choose to visit a competitor’s website instead. Some retailers tackle this issue by using backorders, where an item that is currently unavailable but still in production, is promised to be shipped within a specified timeframe.

This is a win/win for both the customer and the retailer, since the sale is made for the retailer, and the customer gets the product they want. However, managing backorders can present challenges. If an order cannot be fulfilled as promised, it may lead to greater customer dissatisfaction compared to when the item is just out of stock. Additionally, handling backorders poses logistical and financial challenges for the company.

Implementing backorders in your business requires careful consideration.

What is a Backorder?

When an item is unavailable in a seller’s inventory but is still in production or obtainable from the distributor, the customer may be allowed to make the purchase. This purchase order is registered as a backorder, and the seller makes the promise to fulfill it within a specified timeframe.

Backorders, sometimes also referred to as a backlog, signal that the demand for a specific product exceeds what the seller has produced or ordered. This situation might result from inadequate planning, issues within the supply chain, strict policies regarding safety stock, or an unexpected surge in demand for the item.

When considering whether your business should offer backorders, it’s advisable to avoid enabling them for low-cost or readily available commodity products that customers can easily obtain elsewhere. If you do decide to offer backorders, ensure that the profit margin justifies the additional logistical efforts and that you can promptly fulfill those requests. The duration it takes to deliver a back ordered item to the customer depends on various factors:

| To estimate the length of time for a backorder, consider these factors: | |

| Capacity for Customer Service | Dealing with backorders means extra steps and exceptions. Companies equipped with automated order management systems and robust exception handling mechanisms, or those utilizing third-party logistics providers (3PL), can efficiently handle reorders and fulfillment. |

| Rules of the Marketplace | Retailers operating on platforms like Amazon or eBay might opt against accepting backorders due to platform regulations, such as stringent fulfillment deadlines where the restock date typically needs to fall within 30 days of the sale. |

| Your Supply Chain | The longer and more complex a supply chain is for an item on backorder, the longer it will take to acquire sufficient stock to meet demand. There’s a higher probability of the item going out of stock before fulfilling backorders. |

| Capabilities for Dropshipping | Whenever possible, streamlining processes by directly dropshipping back-ordered items from the manufacturer or distributor accelerates fulfillment. |

Backorders vs Out of Stock

When an item is unavailable for purchase because the seller lacks inventory and cannot provide a definite restock date, or if the item is part of a seasonal or limited production, it is considered out of stock. Backordered items are anticipated to become available within a reasonable timeframe.

How Backorders Function

When a company accepts orders, including potential payments for products not currently in stock, it is engaging in backorders.

After accepting backorders, the warehouse management system converts them into purchase orders and forwards them to the appropriate internal department, vendor, or distributor. Customer service teams should inform buyers of an estimated delivery time and explain the payment process.

Retailers might opt to have the supplier ship items directly to customers, or they may receive the items themselves, convert the backorders into sales orders, and ship them to customers after charging their accounts, if applicable.

For a limited number of product codes at a manageable volume, this process is relatively straightforward. However, complications arise when the number or quantity of backordered items increases, or when retailers rely heavily on manual order processes and must align each purchase order with a corresponding sales order during fulfillment.

What is the Purpose of Backorders?

Backorders serve several purposes for companies. For retailers with limited warehouse space, holding a large stock may not be feasible. However, if they can reliably monitor item availability from suppliers, they can prevent overcrowding and excessive storage expenses while confidently accepting backorders.

At times, companies experience unexpected spikes in product demand. Again, contingent upon their ability to monitor additional stock availability, accepting backorders enables retailers to capitalize on those sales opportunities and maintain customer satisfaction.

Small suppliers that primarily rely on drop shipping often routinely accept backorders and place orders with the supplier only once backorders reach a certain threshold. This approach allows these companies to completely avoid inventory holding costs.

Impact of Backorders on Supply Chains

Backorders have repercussions throughout supply chains, imposing additional responsibilities on distributors and manufacturers. In fulfilling backorders, suppliers must generate or acquire extra stock beyond their regular inventory. If there’s insufficient product to fulfill these orders, the pressure is passed up the supply chain, or retailers may be compelled to cancel backorders.

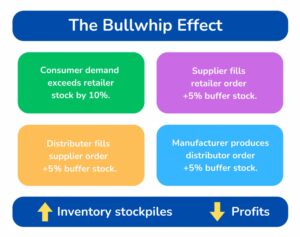

These abrupt shifts in demand can trigger what’s termed a “bullwhip effect,” characterized by an exaggerated response within the supply chain. The farther removed an entity is from the source of backorder demand, the more uncertainty is introduced. For instance, overseas suppliers distant from retailers are unlikely to receive prompt information regarding the causes of backorders. Consequently, they may opt to bolster production to ensure they can meet downstream demand—even if the backorders stemmed from an anomaly, such as an unanticipated heatwave prompting a surge in demand for AC filters in October. Consequently, overall supply chain costs escalate, and retailers may find themselves saddled with surplus inventory.

Understanding the Causes of Backorders

Addressing the underlying causes of backorders represents the initial stage in either preventing or minimizing their occurrence. Let’s examine some common reasons for backorders, which can be viewed as manifestations of inaccurate forecasting and can consequently be alleviated through enhanced inventory forecasting:

Unusual demand or demand surpassing supply:

Occurrences like holiday seasons or unexpected events such as extreme weather conditions may result in atypical purchasing patterns.

Inaccurate forecasting:

Less precise forecasts may result in inadequate safety stock levels and an increased likelihood of backorders.

Supplier or manufacturing challenges:

Issues within the supply chain, such as factory closures or shortages of raw materials, can unexpectedly lead to items being out of stock.

Delayed orders:

Companies relying on safety stock formulas and requiring manual review of purchase orders may encounter delays in restocking, followed by sudden surges in orders. If a company’s upstream supplier has not replenished stock, there may be delays, leading to backorders.

Human errors:

An employee might mistakenly designate an order as a backorder even when the item is available. Alternatively, a retailer may accept a backorder despite the item being out of stock, either due to an error or due to delays in inventory updates.

Accounting for Backorders

Even when equipped with suitable warehouse management systems, handling backorders typically requires different procedures in accounting and customer service. This is because the company must inform buyers about the backorder, specify when they will be charged, and provide an estimated delivery date.

A company’s backlog is typically classified as a subset of sales, indicated either by a dollar amount or the number of units sold or ordered. Instead of treating it as a finalized transaction, the backorder is logged as such in the company’s records. This approach prevents the need for the company to adjust its accounting records if the customer cancels the order or if the company is unable to procure the stock.

Upon recording a backorder, the company proceeds to place the order. Upon receiving the items, the company fulfills the order, delivering the product in accordance with the customer’s purchase order. Alternatively, the items may be drop-shipped directly. Then, the sale is documented and marked as complete.

It’s crucial for companies to assess backorder rates, along with other essential inventory Key Performance Indicators (KPIs) and metrics, such as forecast accuracy and time to receive.

The backorder rate KPI indicates the proportion of a customer’s total orders that involve items on backorder, resulting in delayed delivery. It reflects a company’s effectiveness in stocking high-demand products.

To calculate the backorder rate, use the following formula:

Backorder rate = (number of delayed backorders / total number of orders placed) x 100

Managing Backorder Fulfillment

Ideally, the optimal approach to handling backorders is to not need to accept them. However, in reality, most sellers will encounter this scenario. In such cases, investing in a warehouse management system becomes essential, as it can prevent customer dissatisfaction by providing accurate and real-time data for decision-making. Moreover, it can compile insights based on seasonal trends to forecast supplier performance and anticipate spikes in demand.

Businesses that effectively manage inventory flows in accordance with supplier lead times and adjust purchase orders based on real-time data can prevent stockouts, particularly during periods of peak sales potential.

When faced with the need to fulfill backorders, follow a 5-step process:

- Make amends — Assess whether expressing gratitude to affected customers for their patience through a shipping upgrade or including a complimentary low-cost item is appropriate.

- Inform the customer of the expected delivery date range. Explore whether the customer has placed additional orders that could be bundled with the back-ordered item.

- Convert the backorder into a sales order and authorize shipment.

- Process payment or generate an invoice.

- Dispatch the item and finalize the sale.

But don’t end it there. If there is a substantial number of backorders, consider recalibrating reorder points, establishing a higher safety stock threshold, or reevaluating the inventory forecasting procedure.

Best Practices for Managing Backorders

While some backorders may be inevitable, it’s advisable to adopt best practices to minimize them, thus reducing the risk of a negative impact on your supply chain, such as the bullwhip effect, and addressing challenges like customer dissatisfaction, extended fulfillment periods, and increased backend complexity.

Leading retailers employ the following strategies:

- Consolidate backordered items from a customer’s order before notification, shipping, or billing.

- Establish a timeframe for keeping backorders open and active. The duration varies depending on the business but typically lasts around 30 days.

- Make diligent efforts to procure back-ordered items within the specified timeframe, even if it involves higher costs or manual processes.

- Notify customers promptly if an item cannot be shipped within the designated timeframe and log an entry in your Customer Relationship Management (CRM) system to send an email notification if the item becomes available in the future.

Additional best practices to consider implementing include:

- Maintain open communication with supply chain partners—establishing transparent lines of communication with both upstream and downstream partners reduces assumptions and minimizes the likelihood of overestimating or underestimating demand.

- Educate employees about the drawbacks of backorders and emphasize the importance of delivering exceptional customer service.

Five Strategies for Reducing Backorders

Reducing backorders is achievable through a strategic blend of business methodologies and technological solutions. Here are some steps to consider:

Understand your customers’ preferences and requirements:

Prioritize inventory items based on their significance to customers, allowing you to be discerning about increasing safety stock levels. For instance, a restaurant proprietor may be less forgiving of potatoes being backordered compared to an exotic fruit. Given the low cost of stocking ample potatoes, there’s little justification for running out of them. Conversely, suppose a crucial ingredient for your largest customer’s popular dish is costly and challenging to source, and repeated backorders risk driving them to alternative suppliers. In that case, it’s crucial to maintain a reliable supply chain.

Seek Real-Time Data and Reporting

Securing accurate and near-real-time data reporting serves two essential purposes: firstly, it ensures that your warehouse is promptly alerted to restock items, thus reducing the likelihood of purchasing delays that result in backorders. Secondly, it enables proper customer notification—ideally at the point of purchase—regarding back-ordered items, empowering them to decide whether to retain them in their carts.

Implement System Triggers

These triggers can vary from basic alerts indicating low stock levels to automated notifications to customers regarding the status of their orders or the arrival of new shipments for frequently purchased items.

Establish Backup or Contingency Plans

In instances of backorders, savvy sellers go to great lengths to avoid disappointing valued customers. This may involve sourcing from local suppliers or even procuring the item elsewhere at retail prices.

Diversify Suppliers

Manufacturers or suppliers may also encounter periods of peak demand, whether planned or unplanned. Hence, ordering from a diverse range of sources is integral to sound supply chain management. This process begins with timely purchase orders and involves performance monitoring, including metrics such as productivity, costs, fill rates, on-time delivery, and customer satisfaction.

Customer Service and Backorders

Ensuring customer satisfaction during backorder scenarios is crucial for fostering repeat business.

Customers expect to receive timely updates and information about any delays or modifications. Proactive communication is essential for upholding your company’s reputation. Concrete measures include sending out regular email notifications, furnishing estimated arrival times, and keeping customers apprised of any factors that could hasten or impede their shipment.

In cases where a deposit or full payment was collected and the customer opts to cancel, promptly initiate the refund process.

Manage Inventory and Handle Backorders Efficiently with PALMS™ Smart WMS

PALMS™ Smart WMS offers features to streamline backorder management, by establishing priorities based on predefined rules and criteria. These can be the shipping deadlines, customer priority, order dates, or other essential business objectives. Our WMS automatically identifies and prioritizes critical backorders, ensuring prompt fulfillment as soon as stock becomes available. You can also optimize order consolidation through automation-driven warehouse operations by grouping back orders according to item type, geographical location, and other relevant parameters. With real-time, 360° visibility, back ordered items are closely monitored and allocated for fulfillment immediately upon availability.

Connect with our experts to learn more about digital transformation in your warehouse, and what PALMS™ Smart WMS can do for you!

23/04/24